Personal Protective Equipment (PPE) for Home Inspectors

By Alyssa Cink

Last Updated November 15, 2024

One morning in 1991, a Tennessee power lineman drove to work expecting another routine Monday. His first job of the day: cut down a three-wire voltage system with a residential connection. He’d performed this task more times than he could count. However, one small mistake in his work attire transformed an ordinary Monday into a life-altering experience. He was not wearing gloves designed for handling high-voltage electricity.

The lineman touched an energized overhead conductor with more than 13,200 volts of electricity, causing him to lose both his hands.

This former lineman’s name is Lee Shelby. Thirty years after his accident, Shelby is an internationally recognized motivational speaker who shares his story with today’s employees and teaches the value of workplace safety—notably, the value of personal protective equipment (PPE).

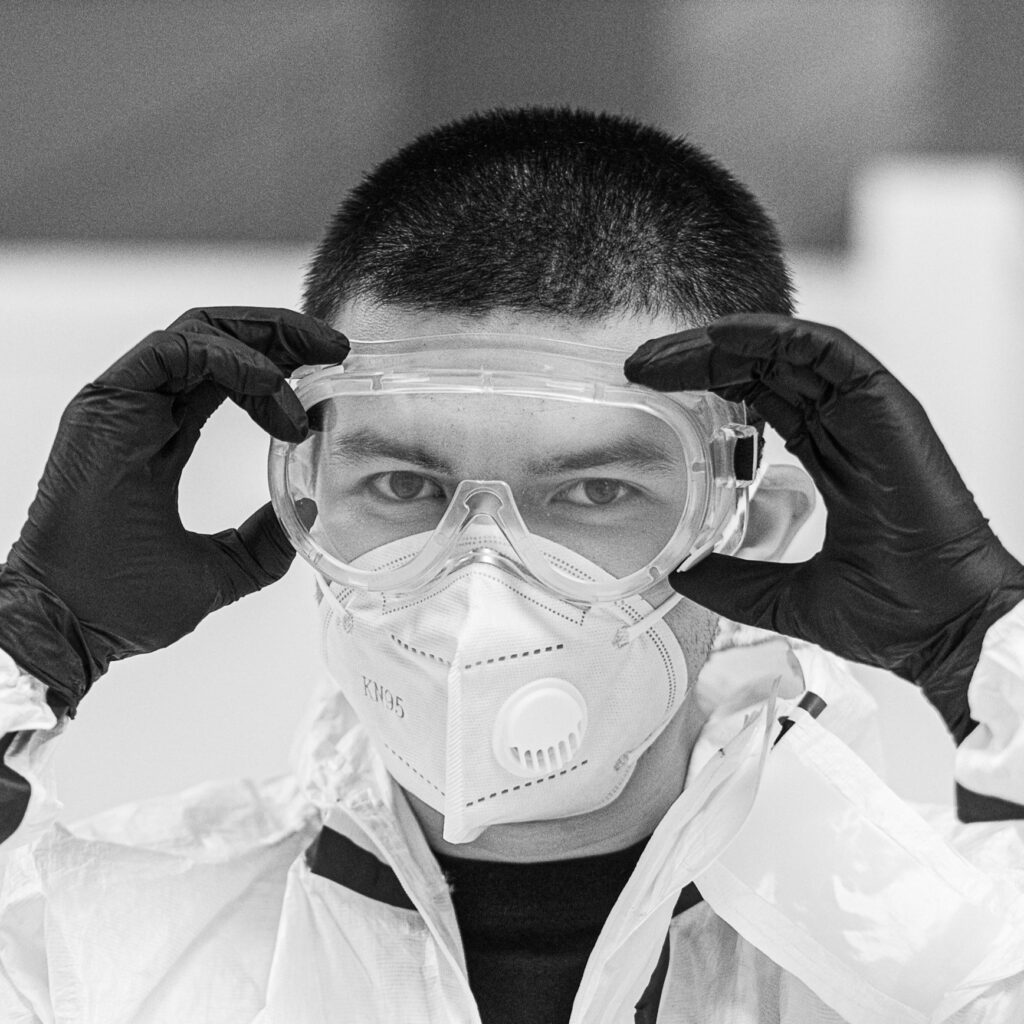

Home Inspectors and PPE

Inspecting homes is a dangerous job. From slippery roofs to aggressive animals, rotted subflooring to electrical exposures, the average home inspector encounters countless perils during their career. Even though Shelby wasn’t a home inspector, many in this industry can relate to his message: No inconvenience is worth more than your life. And taking the right precautions, like wearing personal protective equipment, can mean the difference between a serious injury and a normal Monday.

In this article, we consider the popular PPE equipment types that home inspectors use and experts recommend. We also discuss environmental conditions that often prompt wearing PPE gear, maintenance of PPE, and ways to manage risk while doing so.

What is personal protective equipment?

The Occupational Safety and Health Administration (OSHA) defines PPE as “equipment worn to minimize exposure to hazards that cause serious workplace injuries and illnesses.” Per OSHA’s definition, this article excludes any equipment—like flashlights, ladder tie-offs, caution signs, and insulated screwdrivers—that isn’t worn as a protective covering.

But what PPE is used during a home inspection? There are many types of personal protective equipment. In our PPE guide below, find a personal protective equipment list based on what PPE equipment is used during an inspection most often. Coupled with your inspection scope, this list can help you determine the home inspection PPE requirements for your business.

1. Coveralls

When it comes to PPE clothing, coveralls are most common. Coveralls offer full-body protection from biological, chemical, and electrical dangers. They make for a good protective suit for crawlspaces. In addition to keeping harmful substances away from your skin, coveralls also reduce the likelihood of tracking dirt into your home or the client’s home.

“We suit up in Tyvek suits for every attic and crawlspace regardless of the age of the home,” writes Nonprofit Home Inspections in their blog article. “You don’t know what potential contaminants might be present until you see them, then it’s too late.”

Tyvek coveralls gained popularity in the industry for their tear-resistant, anti-static, lightweight, and chemical-resistant design, according to an article from the International Association of Certified Home Inspectors (InterNACHI). And, because they’re disposable, suits like Tyvek coveralls don’t need to be decontaminated. They’re also available in bulk.

The downside, InterNACHI explains in the article above, is that Tyvek suits are not designed for use near heat or open flames. OSHA requires flame resistant (FR) clothing for employees exposed to certain electrical hazards, such as arc flashes. As such, Tyvek coveralls don’t always meet OSHA’S PPE clothing regulations.

2. Eyewear

2. Eyewear

PPE eye protection is essential. Covering your eyes reduces your risk of eye injuries and diseases. For many workers, this is common knowledge.

Even so, nearly 45 percent of head injuries that cause work absences come from eye-related injuries, writes HexArmor in a blog post. This same post shares that 300,000 workers end up in the emergency room each year as a result of occupational eye injuries. Furthermore, 90 percent of these injuries could have been prevented with well-fitted and comfortable eyewear.

One home inspector experienced this firsthand during a routine inspection. In April 2024, Kelly Marie Hardin of Safe Harbor Home Inspections in North Carolina was in a crawlspace photographing a damaged exhaust line. At that moment, the buyers turned on the dryer, and dryer lint blasted Hardin in the face. Although she immediately rinsed her eyes, one of them wouldn’t clear. Hardin’s doctor had to remove fiberglass that was embedded in her eye.

“Please wear safety goggles and a respirator or at least an N95 mask in the crawlspaces and in attics,” Hardin advised in her Home Inspectors Helping Home Inspectors Facebook post. “Those fiberglass particles are no joke. If any of it gets in your eyes, in your lungs, or on your skin, it can really cause a problem. I have managed to continue my regular inspection schedule despite the injury to my eye, but [it] has not been fun. Be safe out there!”

Which type of eyewear is best for you?

Sealed, splash-proof goggles can protect against environmental factors like:

- Mold spores or sawdust in the air.

- Sparks from electrical panels.

- Splashing liquids, like chemicals or sewage.

- Smoke and other gases.

- Moving or falling debris, like wet or dry cement powder, glass, metal, or fiberglass.

Some eyewear provides better security than others. According to a breakdown of OSHA’s standard, safety glasses are the most common and best protection against smaller particles.

Goggles, when fit snugly against the face and with appropriate venting and anti-fog coating, are chemical eye protection. They’re better for deflecting splashes, sprays, and other liquids, the same article says. Some inspectors even wear face protection shields to protect themselves against electrical exposures, our safety article covers.

“If you look at the OSHA rules, when you’re messing with panels, you’re actually supposed to have a face shield on,” said Alan Grubb of 4U Home, Inc. in Maryland in the above article. “We haven’t required face shields ourselves yet, although I’m very well thinking about it. The more I read up on [electrical hazards], the more they scare me.”

Visit the OSHA PPE gear breakdown and eye protection blog articles from the Center for Construction Research and Training (CPWR), or OSHA’s regulations guide, to learn more about selecting and wearing eye safety gear.

3. Headgear

Headgear helps prevent trauma to the brain, scalp, or skull caused by falling, flying, or low-hanging objects, as well as electrical exposures, OSHA explains.

Home inspectors have two options for protective headgear: bump caps and hard hats. Bump caps look like baseball caps with plastic inserts on the inside. As the name suggests, these hats are ideal for workers prone to bumps and scrapes. Some inspectors prefer them for crawlspaces and attics with low-hanging beams and protruding objects like nails. However, they do not offer the same level of protection as hard hats.

“Because bump caps are tested to a different standard than hard hats, they should never be used where hard hats are required,” explains workplace safety gear provider Ergodyne in their blog post.

Exposure to more serious head injuries, such as electric shocks or impact from falling objects, mandates the use of hard hats, according to OSHA’s standards. Unlike bump caps, hard hats are built with suspension systems. This suspension disperses the force across the surface area and leaves a space between the shell and the skull, which reduces the risk of severe head trauma, Ergodyne writes in the same article.

After trying both, Tim Magorrian of Guardian Angel Home Inspection Services in New York finds the lighter, minimalistic bump cap better suited to crawlspace conditions.

“Bump camps prevent cuts and injuries,” Magorrian said. “They’re usually lightweight. My hard hat’s fine, but [it’s] heavier and [doesn’t] breathe as well.”

4. Respirators

OSHA mandates properly fitted respirators for workers exposed to contaminated air. Some contaminants, like “harmful dusts, fogs, smokes, mists, gases, vapors, and sprays,” put workers at risk of lung cancers, diseases, and even death, OSHA’s website explains.

Mike Leggett of the BrickKicker of Georgia believes respiratory protection is essential for him and his inspector employees.

“Getting a proper respirator is critical,” Leggett said. “Repeatedly breathing contaminated crawlspace air will take a cumulative toll on your body. Our inspectors are forbidden from entering an attic or a crawlspace without a proper respirator and headlamp.”

What is the best respirator mask for home inspectors? For selecting a respirator, inspectors may choose between half and full-face designs. Half-face respirators cover the nose and mouth, whereas full-face respirators also protect the eyes. Although better equipped for defense against toxins, full-face respirators make breathing a challenge, InterNACHI’s PPE gear guide suggests. While moving in hot, cramped, or stuffy areas, inhibited breathing can quickly escalate from uncomfortable to dangerous.

That’s why, in their PPE gear factsheet, OSHA calls workers to wear NIOSH-approved respirators, receive a medical evaluation, and complete prior training. This helps ensure that you’re wearing your respirator safely and effectively.

5. Gloves & Pads

Depending on the space they’re inspecting and the standard(s) of practice (SOP) they follow, some inspectors find personal protective gloves more useful than others.

For example, an inspector may put on gloves before entering an attic to protect their skin from harsh surfaces, cuts from nails and other sharp objects, and temperature extremes. Additionally, crawlspaces are especially infamous for mold, sewage, animal carcasses, fecal matter, and other substances inspectors wouldn’t want to touch with their bare hands.

It’s essential to match the equipment to the hazard. Elbow, forearm, and knee pads worn underneath coveralls, or even padded forearm gloves, provide extra cushioning and reduce damage while crawling. Insulated rubber gloves can protect your hands from electrical injuries, depending on their voltage rating, explains OSHA, making such gloves potentially good high voltage personal protective equipment. Rubber also makes for chemical resistant gloves. Meanwhile, inspectors more concerned about moderate heat, cuts, or burns may opt for leather gloves.

Read from page 22 of OSHA’s PPE gear guide for a more detailed breakdown of hand protection gloves.

6. Footwear

As Marilyn Monroe famously said, “Give a girl the right shoes and she can conquer the world.” It turns out, the quote also applies to home inspector shoes.

A good pair of shoes can make a big impact, especially when you work on your feet all day. Proper and protective footwear minimizes foot infections, injuries, and conditions like bunions; improves posture; offers additional support; reduces foot pain; and protects you in hazardous work conditions, explained the nonprofit Soles4Souls in a blog article. Furthermore, under OSHA regulations, employers may be required to provide and ensure the use of protective footwear.

What are the best shoes for home inspectors? What type of footwear protects you from chemicals and provides extra traction on slippery floors?

The safety education website realsafety.org shares the following considerations for foot safety:

- Falling materials? Consider steel-toed boots.

- Worried about stepping on sharp objects, like nails? Look for thick, heavy-duty soles.

- Possibility of electrical dangers? Choose non-conducive shoes made from materials like rubber.

- Frequently climb ladders and slippery surfaces? Properly fitting shoes with good traction can prevent slips and falls. Brands like Cougar Paws also offer shoes specifically for walking roofs. Furthermore, anti-skid shoe covers, like these from ShuBee, can be worn in the client’s home to keep their floors clean.

- Live in a cold state with frequent rain and snow? Waterproof and insulated shoes help inspectors stay healthy while working in frigid temperatures.

For more details about selecting the right home inspector shoes, see this guide from the occupational safety and health magazine EHS Today.

Managing Risk with Personal Protective Equipment

Whether you’re a solo inspector, inspecting for another business, or managing a multi-inspector firm, selecting—or not selecting—the right PPE gear can open you up to risk. Below we offer suggestions for limiting your liability and prioritizing inspector safety.

Educate and communicate about PPE gear.

Educate and communicate about PPE gear.

If you own a multi-inspector firm, you need to educate your inspectors about PPE and communicate its importance. Some ways OSHA suggests include:

- Identifying PPE gear that’s appropriate for the job,

- Making sure employees have and wear this personal safety equipment,

- Re-evaluating their PPE’s effectiveness and updating as necessary, and

- Training employees on appropriate use and maintenance.

As an employer, understanding these standards helps keep your employees safe, happy, and productive. Also, if an employer neglects to purchase mandated PPE for their staff, and their negligence results in an inspector’s illness, injury, or death, a negligence claim could lead to a lawsuit. Furthermore, this familiarity with PPE guidelines keeps employees aware of their rights and what’s expected of them.

How do you know if PPE is required? And where can you find PPE requirements?

Even if you’re a sole proprietor and not required to follow OSHA regulations, inspectors should familiarize themselves with them to stay safe on the job. To best manage your risk, stay up-to-date on OSHA’s reference and reading materials to verify your compliance with workplace safety standards. Know what the standards mean—including what is the standard PPE equipment and what is the minimum essential PPE—and how they apply to you. If you’re looking for more guidance, consider this HSI training program or OSHA’s online Education Center for certification courses on hazard assessment, prevention, PPE, and even first aid. Visit OSHA’s website to learn more about the resources available to small employers.

Perform routine personal protective equipment inspections.

How often should you inspect PPE?

“Like humans, personal protective equipment has a life expectancy,” wrote Marianne Wait in a United Rentals safety article.

PPE is only safe and effective when it’s in good condition. As such, inspectors should routinely check their equipment for signs of weathering and damage. These visual inspections will help you decide when to repair your PPE or replace it entirely.

Read the United Rentals article above and your manufacturer’s recommendations to learn what you should be looking for.

How do you replace defective PPE? Often, it’s a matter of buying new PPE items to swap in for the defective ones. If you find yourself replacing some of your PPE gear more often than you think you should, research that PPE item’s average lifespan, and consider changing materials or manufacturers.

Prioritize inspector safety over convenience.

Mike McFadden of Hero Inspection Services in Florida acknowledges in his blog article that wearing PPE can be frustrating. Inspectors may feel pressure to remove their PPE so they can perform the inspection faster. However, in doing so, these inspectors open themselves up to undue risk.

“Don’t take [PPE] off until the work is done,” McFadden writes. “Most PPE is inconvenient and sometimes also uncomfortable. It might be tempting to take them off just to get the job done quicker. But many times, that is when injuries happen.”

Rushing also means you’re more likely to make mistakes. Follow McFadden’s advice and avoid speeding through your inspections and reports. After all, your long-term well-being will always be more important than a short-term inconvenience. Inspector safety needs to be the priority.

If you own a multi-inspector firm, be prepared in case your employees push back. Communicate your company’s PPE equipment requirements clearly and frequently. One of the best ways you can combat employees’ resistance to PPE policies is to lead by example. By debunking common PPE myths, maintaining open communication, and sticking to your policies, you can protect your team and your business from unnecessary risk.

Carry workers’ compensation insurance.

If you or one of your home inspectors is injured during an inspection, workers’ compensation benefits may be available to you.

Workers’ comp insurance provides employees who suffer from work-related injuries or diseases with access to medical and wage benefits. Unlike general liability (GL) insurance, which covers inspection-related bodily injury and property damage claims for non-employees, workers’ compensation looks out for you and the people who work for your company.

“One accident can not only hurt you and maybe put you out of business, but more importantly, that employee has to have a way of making a living and getting his bills paid for if it happens on the job,” said Alan Grubb of 4U Home, Inc. in Maryland in a previous article.

By covering job-related injury and illness costs, workers’ comp protects both employees and employers. And employees work under less financial risk knowing they have on-the-job protection. Additionally, employers limit their liability and deter litigation.

“If you have any employees, they need to have workman’s comp,” Grubb said. “The amount that it costs for workman’s comp is minor [compared] to what it could cost you or your employee if you didn’t have it.”

What expenses can workers’ comp cover?

While it isn’t quite “PPE insurance coverage,” workers’ comp can come in handy when PPE fails. In inspection-related injury cases, workers’ comp coverage can assist inspectors in the following ways:

- Medical Bills. From doctor appointments to hospital visits, to medications and mobility aids, workers’ comp helps pay to treat employee illnesses and injuries. Workers’ comp can even help inspectors pay for their mileage when traveling to receive medical care.

- Lost Wages. Sometimes, inspection-related injuries and illnesses are bad enough that employees are unable to work. Workers’ comp can pay a percentage of the money the employee would be earning if they weren’t in recovery.

- Rehab Benefits. Workers’ comp policies may offer medical rehab benefits, like physical therapy, to help employees recover. Additionally, they can help pay for vocational rehab for severely injured employees unable to perform their previous jobs. By helping these injured workers attain new job-specific skills, vocational rehab helps them return to work in a different role.

- Death Benefits. If an employee died, workers’ comp insurance may help cover funeral costs and lost income for the employee’s family.

Note that, since states regulate workers’ comp coverage, the amounts insurers will pay for the above benefits vary from state to state.

“Each state has its own regulations as to the amount and duration of lost income benefits and medical or rehabilitation services,” said Brianne Smith, InspectorPro broker and workers’ comp specialist. “However, workers’ comp is a no-fault coverage nationwide. That means it will provide coverage no matter who was at fault.”

Get a quote for workers’ comp for home inspectors today and complete our application.

Protect yourself with personal protective equipment and workers’ comp.

Now you know what personal protective equipment you need to keep you and your employees safe. Now do your part to abide by state law and protect your employees and your business by carrying workers’ compensation insurance. And do so with a company prepared to meet the inspection industry’s unique coverage needs.

“Things happen when you go out and inspect. And if something goes wrong, you want to make sure that you are covered…. I don’t want to be the one who doesn’t have the proper insurance in case something goes wrong,” said Walter L. Williams from PPT Inspections in a previous article. “For a few dollars more, [workers’ comp] is going to give you peace of mind.”

For a list of all the best tools and equipment for home inspectors, including what is not considered PPE, check out our checklist here.