What Are Good Inspection Report Writing Practices for Defect Classification?

Last Updated November 9, 2023

Defect classification is difficult for home inspectors, especially when so many issues are deeper and more serious than they appear. An inspector in Florida found this out for himself when both his phone and emails started blowing up with messages from a past client about major foundation damage.

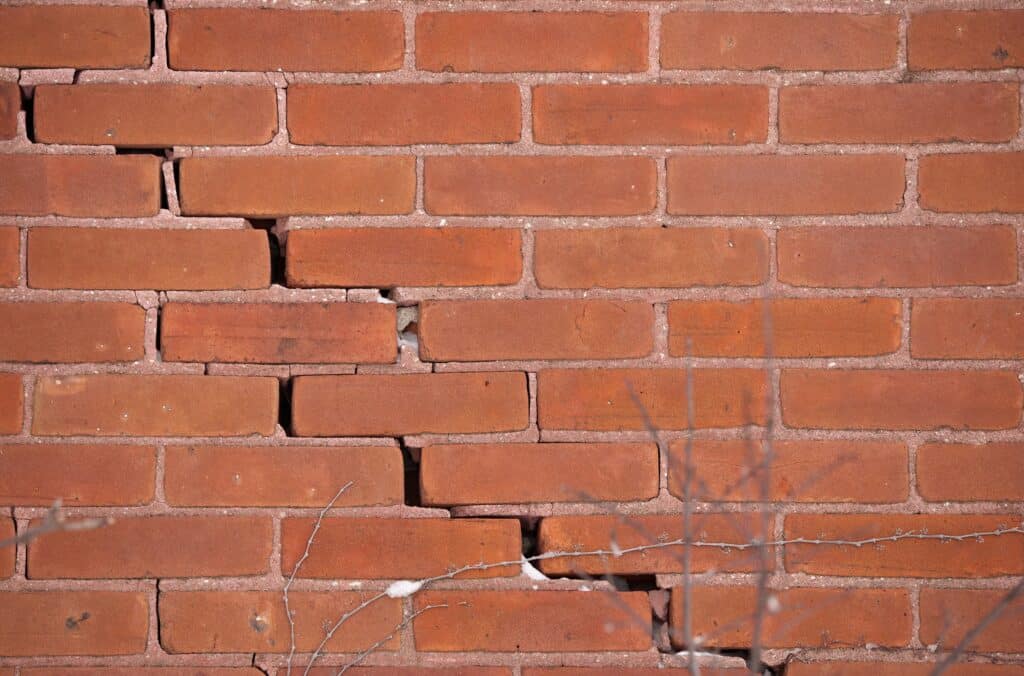

Three months before, he inspected the single-story home, where he noticed cracks in the brick veneer siding. Since he hadn’t observed any other signs of settlement, he classified the issues as a “minor concern,” the lowest and least alarming designation for defects in his reports.

While his report did indicate that minor concerns have the potential to become moderate or serious, the definition primarily communicated that minor concerns were low-risk, DIY items not worth worrying about. The main piece of advice for a minor concern: “monitor” the issue.

Now, picture the client’s surprise when they pulled up the carpet and found a deep crack in the slab beneath the bedroom and sunroom. The crack was a symptom of foundation damage—and so was the cracking exterior of the brick siding. Suddenly a minor concern for the client became a major concern that they wanted the inspector to pay for. They requested that he pay $17,000 for underestimating the importance of some “minor” cracks.

This situation provides a valuable lesson for inspectors: if you want to write a good inspection report, be cautious in your defect classification.

How are defects classified when writing an inspection report?

Whether you learned how to write an inspection report from a training school or a mentoring inspector, you know there are as many styles of classifying defects as there are inspection businesses.

We asked inspectors on social media about how they handled defect classification.

Brad McLeese from HomeGuard Inspections classifies defects this way, which focuses on replacement and repair:

- Repair/Replace

- Budget for Replacement

- Evaluate

Chuck Lambert from Sunrise Inspection Services categorizes based around the expected action from the client:

- Safety Concerns

- Further Evaluation

- Corrections Recommended

- Recommended Upgrade

Frank Anarumo from Anarumo Inspections Inc. focuses more on severity in this style of defect classification:

- Minor (DIY or informational)

- Moderate (contact a qualified professional)

- Health and Safety (immediate concern)

As you can see, there are some general similarities, such as severity classification or setting expectations for when or how clients should attend to the issue. They all try to serve the same purposes: directing the clients’ attention and setting general measurements for the severity of an issue.

Note that defect classifications don’t tell the full story and, therefore, aren’t meant to exist on their own. After providing a general understanding of the problem through the defect classification, inspectors should then describe the problem in detail and explain what it could mean for their client.

The “Don’ts” of Defect Classification

While classifying defects can provide a good roadmap for clients, many inspectors have misunderstood how to use them. Misusing classifications in your reports can lead to clients misunderstanding the defects you uncover, which can then lead to complaints and claims.

Here are some common “don’ts” to avoid when writing an inspection report.

Don’t use the word “monitor.”

When you include commentary or recommendations in your report, you are giving the client something to act upon. For some inspectors who worry about over or underrepresenting a defect in their report, they may become too comfortable with the word “monitor,” just like the inspector from Florida in our initial story. Within his defect classification definitions, he said that minor concerns should be monitored.

Here’s the problem: “Monitor” is a very passive word. It’s almost an invitation to ignore a potential issue until or unless it gets worse. Then, the client inevitably becomes unhappy that they weren’t told to consult a professional earlier.

If a defect (or even a potential defect) is worth monitoring, recommend a more in-depth inspection from a specialist in that field. That way, if things blow up, you have much more defensibility as the person who suggested they act rather than another inspector who suggested that they wait and see. While those who use the word “monitor” are not necessarily at fault, it is a more difficult position to defend because of the relaxed nature of the advice.

Don’t overstep the scope of an inspection.

Many types of defect classification are based around repairs. “Does this defect need to be repaired immediately?” becomes the primary question when that’s the basis of the classification method you use. But many of the standards of practice (SOPs) for inspectors caution against describing the timeline, the cost, or the methods of repairs.

Suggesting how long a system or component will last, or how much it may cost to repair, or even how the client should go about getting the defect repaired, are all outside the SOP. And exceeding your SOP —especially if the information you provide is incorrect—can land you in hot water.

Don’t let your classification definitions do the talking.

You are supposed to be fact based, not assumption based. Yet, classifications are, at their core, assumption based. After all, they require you to decide what information is more important to the client. But your priority list may not be the same as your client’s.

Your defect classifications should guide your clients as they read your inspection report; they should not do the bulk of informing. Keep your classifications simple and your explanations and advice for each area of the home and defect in-depth and informative.

How to properly use defect classifications in a good inspection report.

We started out with the “don’ts” of using defect classifications so that you know that it isn’t as simple as “pick a system and roll with it.” You need to be aware of the pitfalls. But, luckily for you and your client, you can still provide defect classifications in your report without misdirecting your client from important information. Here’s how.

Know the purpose of defect classification.

For Ron Pritiskutch of Crestview Home Inspections, Inc., defect classifications are an organizational tool that can help clients comprehend reports.

“Repairing a roof wouldn’t be something that would be considered routine homeowner maintenance,” Pritiskutch said, “[but] maybe there’s some caulking or something that’s dried and separating on the exterior of the home. I think classifying something like that as a maintenance item, most people could understand better.”

While contextualizing your observations with defect classification, Pritiskutch cautions against quantitative reporting, which inspectors do by ranking defects by severity. Just because you’re creating a classification doesn’t mean that you know the full extent of a potential issue, Pritiskutch explained.

Here’s an example of how Pritiskutch avoids the hazard of scoring defects in his inspections: While inspecting a porch, he noted dry rot on the single supporting post of the header. The potential danger of the post losing its integrity and causing the header to fall was worth classifying the defect as “severe,” even if the repair costs were not likely to be expensive.

“As home inspectors, many times we do not know the full scope of repairs,” Pritiskutch said. ”There may be additional defects in a particular system and/or concealed damage that we are not aware of.”

So, when classifying your defects by supposed severity, disclaim the limitations and explain the purpose. Doing so will protect you if the defect is more severe than it appears. Additionally, always encourage clients to have a professional or specialist perform a more in-depth inspection to confirm the quantitative aspects of those defects.

Set the expectation in the inspection agreement.

While it is important to define your defect classification in the report, it is even more vital that you define what a defect itself is in your inspection agreement. A report is something you deliver to the client, but the inspection agreement itself is the contract between you and your client. If you define what the base understanding of a defect is within the agreement, then that will be more important than stressing over your defect definitions in the report. One of the best ways to do so is to state the standard of practice (SOP) you will use in your agreement.

In InspectorPro’s model inspection agreement, for example, we state what is excluded, which defects are specifically inspected for, as well as the definition of defects. Learn more about our agreement here.

Photos can add objectivity.

Let’s say that you get accused of misleading the client by incorrectly classifying or reporting the severity of a defect in your report. How can we know who is correct in such a he-said-she-said situation? Photographs.

Pritiskutch often uses photos to help him stick to the facts while reporting. If you describe what both you and the client can see in the photo, you’ll be less likely to make assumptions and report unfounded quantitative aspects of the defect.

When considering potential future arguments or claims from clients, taking photos of defects, non-defects, entire rooms, and important systems in the house can be the objective backup you need to defend your subjective defect classifications. If you require proof that a problem did, in fact, appear to be a minor concern, the photograph showing that defect can be an incredible defense.

Further, in a situation where a defect has worsened since the inspection, like roof or foundation damage often does, you can prove that the defect had initially been classified correctly, and that the increased severity of the problem is not your fault.

Get peer reviewed often.

Just like any professional, it’s easy to fall into bad habits or assumptions after performing tens or hundreds of inspections. Who can say that you aren’t regularly misclassifying certain types of defects? Another set of eyes may be just what you need to polish your inspection report writing skills.

If you don’t have a mentor in the inspection field already, try going to a local organization or association. Or, while taking continuing education courses, get to know your peers and the instructor so that they can be a source of learning for you. While you may feel vulnerable or nervous, asking an experienced inspector to review one of your reports and give general feedback (including feedback on how well you did with defect classification) can help you refine your writing and sharpen your skills and judgment.

Have another inspector peer review one of your reports at least once a year and your reports will have a distinct improvement over home inspectors who don’t.

When in doubt, throw it out.

If you are worried about an improper defect classification causing you problems, you can simply not classify them. You aren’t required to provide defect classifications, and if it would be more of a hindrance for you than a help to your clients as a roadmap, leave it out.

Many inspectors choose to leave them out because they worry about being too subjective. This is the main reason why John Keener of Mountaineer Inspection Services doesn’t use a system of defect classification. “I have either informational items or defects,” Keener said.

He believes that giving the information as-is, without any parameters on how important it is, will allow the client to decide the importance of an issue based on their circumstances and the provided description and information in the report.

So, remember: if defect classifications are becoming a stumbling block rather than a roadmap, don’t bother with them.

You aren’t perfect. But your protection can be.

Following tips like the ones above can be an amazing help, but even the best home inspectors make mistakes. And even for those who don’t, there’s no guarantee that an exceptionally angry and persistent client won’t do everything in their power to take you through a messy and expensive lawsuit. You don’t have to be perfect, however, to have the perfect protection for your home inspection business.

Getting help from an experienced and qualified team can make all the difference when you are trying to keep a small mistake from blowing out of proportion with an upset client. For example, our claims handling team helped that Florida inspector resolve the “minor” crack issue for just $745—a far cry from the $17,000 that the client requested for a misdiagnosed crack in the brick siding.

Our team at InspectorPro Insurance has helped many other inspectors at every level in the industry find peace of mind through insurance protection. Let us fill in where you may fall short. Get your quote here.